- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on March 13, 2023

What is the difference between ACSR and AAAC?

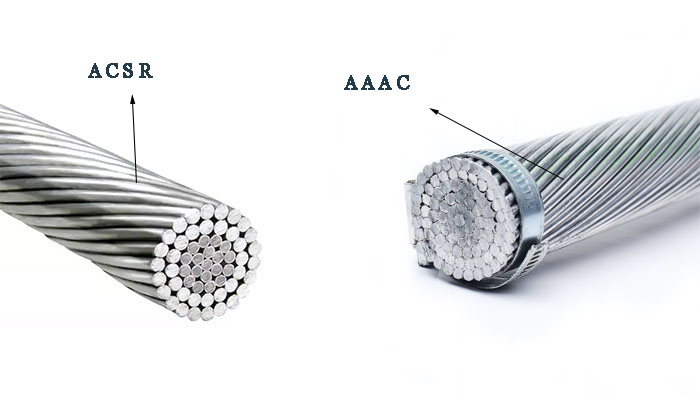

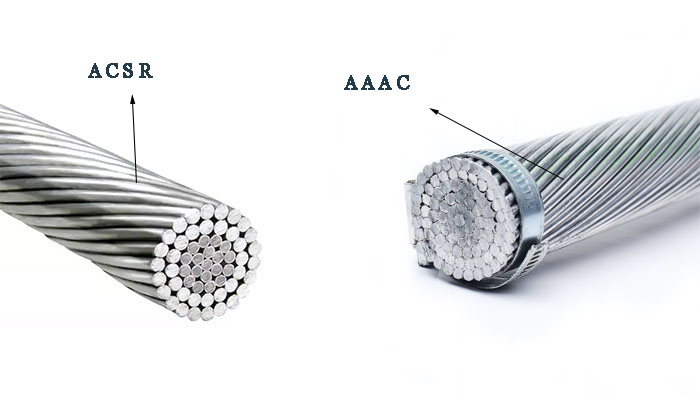

ACSR (Aluminum Conductor Steel Reinforced) and AAAC (All Aluminum Alloy Conductor) are both types of overhead conductors used in power transmission and distribution systems. The main differences between ACSR and AAAC are their construction and material properties.

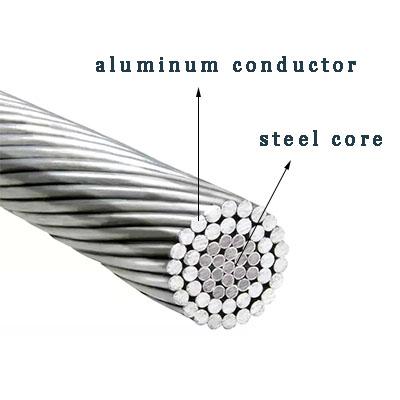

ACSR is a type of overhead conductor that consists of a central steel core surrounded by one or more layers of aluminum wire. The steel core provides mechanical strength, while the aluminum wires provide conductivity. ACSR is commonly used in high voltage transmission lines where mechanical strength is important.

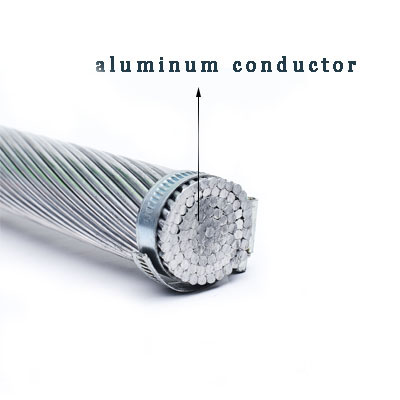

AAAC is an all-aluminum alloy conductor that does not contain any steel. AAAC conductors are composed of aluminum alloy strands that are similar in diameter to ACSR wires, but without the steel core. The absence of steel means that AAAC conductors are lighter in weight and have a higher conductivity than ACSR conductors. AAAC is commonly used in low and medium voltage distribution systems.

In summary, ACSR has a central steel core and is used in high voltage transmission lines where mechanical strength is important, while AAAC is an all-aluminum alloy conductor that is lighter in weight and has higher conductivity, making it suitable for low and medium voltage distribution systems.

ACSR (Aluminum Conductor Steel Reinforced) and AAAC (All Aluminum Alloy Conductor) are both types of overhead conductors used in power transmission and distribution systems.

They differ in several conceptual ways:

1.Material Properties

ACSR has a steel core that provides mechanical strength, while AAAC is made up of an all-aluminum alloy conductor that is lighter in weight and has a higher conductivity than ACSR conductors.

2.Construction

ACSR has a central steel core surrounded by one or more layers of aluminum wire, while AAAC is an all-aluminum alloy conductor that does not contain any steel.

3.Use

ACSR is commonly used in high voltage transmission lines where mechanical strength is important, while AAAC is used in low and medium voltage distribution systems.

4.Cost

ACSR is generally less expensive than AAAC because of the lower cost of steel compared to aluminum alloys.

5.Sag and Tension

ACSR has a higher sag and tension than AAAC due to the presence of the steel core.

6.Installation

ACSR requires special tools and techniques for installation because of the steel core, while AAAC is easier to install because it is all-aluminum.

ACSR and AAAC have different material properties, construction, use, cost, sag and tension, and installation requirements, which make them suitable for different applications in power transmission and distribution systems.

Differences between ACSR and AAAC in application

ACSR (Aluminum Conductor Steel Reinforced) and AAAC (All Aluminum Alloy Conductor) are both used as overhead conductors in power transmission and distribution systems, but they differ in their application due to their specific properties. Here are some key differences:

1.Mechanical Strength

ACSR has a higher mechanical strength than AAAC, making it more suitable for high voltage transmission lines that require greater mechanical stability and support.

2.Conductivity

AAAC has a higher conductivity than ACSR, which means it can carry more current with less power loss. This makes it suitable for low and medium voltage distribution systems where efficiency is important.

3.Weight

AAAC is lighter than ACSR, which makes it easier to handle and install. This makes it more suitable for situations where the weight of the conductor is a concern, such as in difficult terrains.

4.Temperature

AAAC has a higher resistance to temperature changes than ACSR, making it more suitable for use in areas with extreme weather conditions.

5.Corrosion Resistance

AAAC has better corrosion resistance than ACSR, making it more suitable for use in coastal areas or in areas with high levels of industrial pollution.

The choice between ACSR and AAAC depends on the specific application and the requirements of the power transmission and distribution system. ACSR is generally more suitable for high voltage transmission lines where mechanical strength is important, while AAAC is more suitable for low and medium voltage distribution systems where conductivity and efficiency are critical factors.

How should the transmission line choose ACSR and AAAC?

The choice between ACSR (Aluminum Conductor Steel Reinforced) and AAAC (All Aluminum Alloy Conductor) for a transmission line depends on several factors, including the voltage level of the line, the distance the line needs to cover, the environmental conditions in which the line will operate, and the cost of the conductors. Here are some key factors to consider:

1.Voltage Level

ACSR is typically used in high voltage transmission lines, while AAAC is used in low and medium voltage distribution systems. For high voltage transmission lines, the mechanical strength of ACSR is essential, while for low and medium voltage distribution systems, the conductivity of AAAC is important.

2.Distance

ACSR is generally more suitable for long distance transmission lines because it has higher mechanical strength, which allows it to support its own weight and resist the stress of the wind and weather. In contrast, AAAC is better suited for shorter distance distribution lines where its higher conductivity can help to reduce energy losses.

3.Environmental Conditions

AAAC has better corrosion resistance than ACSR, making it more suitable for areas with high levels of industrial pollution or coastal regions where salt spray is present. ACSR is more resistant to mechanical damage from weather or animals, making it more suitable for areas with high winds or where there is a risk of falling branches.

4.Cost

The cost of the conductor is an important consideration in any transmission line project. ACSR is generally less expensive than AAAC, but the cost difference may be offset by the longer lifespan and lower maintenance requirements of AAAC.

In summary, the choice between ACSR and AAAC for a transmission line depends on several factors. ACSR is typically used for high voltage transmission lines over long distances and in areas with harsh weather or animal activity. AAAC is more suitable for low and medium voltage distribution systems, areas with high pollution or salt spray, and shorter distance lines where efficiency is important. The cost of the conductor should also be considered in the decision-making process.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024