- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

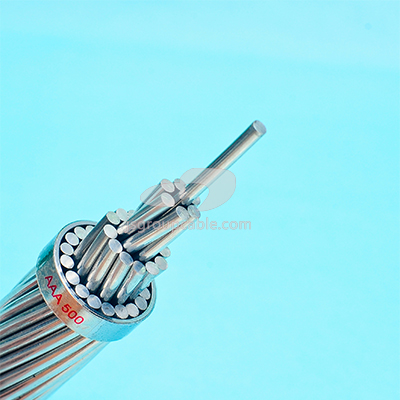

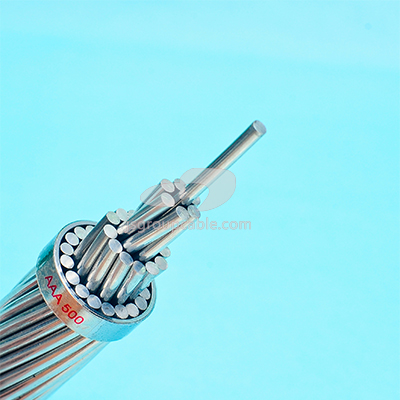

AAAC Conductor

AAAC Conductor

AAAC stands for "All Aluminum Alloy Conductor", which is an electrical conductor made of a central stranded core of aluminum alloy wires surrounded by one or more layers of aluminum alloy wire strands.

- Description

1.Application Of AAAC Conductor

AAAC conductors are widely used in overhead power transmission and distribution systems. Some specific applications of AAAC conductors include:

High-voltage transmission lines:

AAAC conductors are commonly used in high-voltage transmission lines where high strength and low electrical resistance are required.

Distribution lines:

AAAC conductors are used in distribution lines for power transmission from substations to homes and businesses.

Railway electrification:

AAAC conductors are used in overhead electrification systems for railways.

Solar power plants:

AAAC conductors are used in the transmission lines of solar power plants to transmit the power generated by solar panels to the grid.

2.Construction Of AAAC Conductor

The structure of an AAAC (All Aluminum Alloy Conductor) conductor is similar to that of other stranded conductors, with a central core of multiple aluminum alloy wires surrounded by one or more layers of aluminum alloy wire strands.

The individual wires that make up the core and the outer layers of the conductor are stranded together in a specific pattern to provide optimal mechanical strength and electrical conductivity. The most common stranding patterns for AAAC conductors are concentric-lay-stranded, helical, and reverse concentric-lay-stranded.

The number of wires in each layer and the overall diameter of the conductor can vary depending on the specific application requirements. For example, AAAC conductors used in high-voltage transmission lines typically have a larger diameter and a greater number of wires than those used in low-voltage distribution lines.

The aluminum alloy used in AAAC conductors is chosen for its high strength-to-weight ratio, excellent conductivity, and resistance to corrosion. The most common alloys used in AAAC conductors are 6201 and 6101, which contain small amounts of other elements such as magnesium and silicon to improve their mechanical and electrical properties.

3.Standards Of AAAC Conductor

All Aluminum Alloy Conductor meet or exceed the following standards: IEC61089, BS3242, DIN48201, ASTMB399, BS EN50183, GB/T 1179-2008.

4.Parameters Of AAAC Conductor

| Code Name | Size (KCM) | Strand | Approx.EC Cond with Equivalent Resistance | Stranding | Diameter(in) | Cross Sectional Area (Sq in) | Weight per 1000ft (lbs) | Rated Strength (lbs) | Resistance Ohms/1000ft (lbs) | ||

| Individual Wires | Complete Cable | DC@ 20℃ | AC@ 75℃ | ||||||||

| Akron | 30.58 | 7/w | 6 | 6/1 | 0.0661 | 0.198 | 0.0240 | 28.7 | 1110 | 0.659 | 0.785 |

| Alton | 48.69 | 7/w | 4 | 6/1 | 0.0834 | 0.250 | 0.0382 | 45.7 | 1760 | 0.414 | 0.493 |

| Ames | 77.47 | 7/w | 2 | 6/1 | 0.1052 | 0.316 | 0.0608 | 72.7 | 2800 | 0.260 | 0.310 |

| Azusa | 123.3 | 7/w | 1/0 | 6/1 | 0.1327 | 0.398 | 0.0968 | 115.7 | 4460 | 0.163 | 0.195 |

| Anaheim | 155.4 | 7/w | 2/0 | 6/1 | 0.1490 | 0.447 | 0.1221 | 145.9 | 5390 | 0.130 | 0.154 |

| Amherst | 195.7 | 7/w | 3/0 | 6/1 | 0.1672 | 0.502 | 0.1537 | 183.7 | 6790 | 0.103 | 0.123 |

| Alliance | 246.9 | 7/w | 4/0 | 6/1 | 0.1878 | 0.563 | 0.1939 | 231.8 | 8560 | 0.0816 | 0.0973 |

| Butte | 312.8 | 19/w | 266.8 | 26/7 | 0.1283 | 0.642 | 0.2456 | 293.6 | 11000 | 0.0644 | 0.0769 |

| Canton | 394.5 | 19/w | 336.4 | 26/7 | 0.1441 | 0.721 | 0.3098 | 370.3 | 13300 | 0.0511 | 0.0610 |

| Cairo | 465.4 | 19/w | 397.5 | 26/7 | 0.1565 | 0.783 | 0.3655 | 436.9 | 15600 | 0.0433 | 0.0518 |

| Darien | 559.5 | 19/w | 477.0 | 26/7 | 0.1716 | 0.858 | 0.4394 | 525.5 | 18800 | 0.0360 | 0.0431 |

| Elgin | 652.4 | 19/w | 556.5 | 26/7 | 0.1853 | 0.927 | 0.5124 | 612.4 | 21900 | 0.0309 | 0.0371 |

| Flint | 740.8 | 37/w | 636.0 | 26/7 | 0.1415 | 0.991 | 0.5818 | 695.5 | 24400 | 0.0272 | 0.0327 |

| Greely | 927.2 | 37/w | 795.0 | 26/7 | 0.1583 | 1.108 | 0.7282 | 870.4 | 30500 | 0.0217 | 0.0263 |

Product Category

Latests News

-

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024 -

The 135th China Canton Fair

March 20, 2024