- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on November 10, 2023

What are the commonly used wires and cables for fire protection?

Among the fires in our country, fires caused by wires and cables account for a large proportion. During a fire, the flammable insulation layer and sheathing materials in wires and cables are ignited, causing the fire accident to further expand. The harmful gases released by the ignition of the insulation layer and sheathing materials of wires and cables can cause casualties and indirectly hinder firefighting personnel from putting out fires. The occurrence of fire will also cause the power supply lines of fire-fighting machinery and equipment to be damaged, making it impossible to ensure the normal operation of fire-fighting electrical equipment, delaying fire-fighting time, and causing great losses to personnel and property.

What are flame retardant wires and cables?

Flame-retardant wires and cables are wires and cables that have the ability to prevent or slow down the occurrence or spread of flames. That is, under the required experimental conditions, the wires and cables are ignited. After the open flame is removed, the spread of flames on the wires and cables is only within the limited range and Can be destroyed on its own. Flame-retardant wires and cables are not flame-retardant cables. They only add flame-retardant materials to the cable sheath and sheath layer so that the cables will not burn in the fire. When the external open flame subsides, after a period of time It will rest on its own.

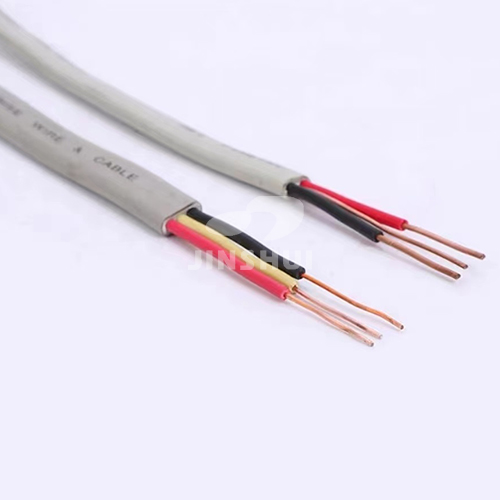

What are the commonly used wires and cables in fire distribution lines?

Fire cables use new oxygen-insulating, flame-retardant and refractory materials, which have the characteristics of no melting, no melting, no prolonged burning, low smoke, low halogen, and slight toxicity. When the cable encounters a flame, the original flexible metal compound will be converted into insoluble metal oxide and water, and the heat O2 will be cut off. The intrusion of the internal insulation layer makes it impossible for the internal insulation layer to burn. The oxygen barrier layer separates crystal water when heated and absorbs a large amount of latent heat of evaporation, which will greatly reduce the temperature of surface combustibles. Fire cables automatically extinguish fires (the flame is 950-1000°C).

The electricity used for fire protection equipment in modern buildings is divided into two categories:

1. AC strong current part

It mainly involves fire water pumps, voltage stabilizing pumps, fire elevators, various types of smoke prevention and exhaust fire fans, fire shutters, electric smoke screens, Class B emergency lighting and evacuation indication systems (this article defaults to Class B systems based on the actual situation on site) AC 220V), Class A emergency lighting and evacuation indication system distribution lines from the power distribution room to the on-site control cabinet.

2. DC weak current part

It mainly involves the distribution lines from the Class A emergency lighting and evacuation indication system to the on-site emergency lighting and evacuation indication signs from the local control cabinet. Distribution lines used to transmit information and control signals between on-site firefighting equipment and firefighting hosts, such as automatic fire alarms, firefighting linkage controls such as water pump start, smoke prevention and exhaust fan start, fire elevator emergency landing, automatic fire extinguishing equipment action, electric fire door, Control circuits for the operation of electric smoke exhaust windows, fire shutters, electric smoke screens, electric dampers of smoke prevention and exhaust systems, etc., feedback signal circuits for the action signals of the above types of fire protection equipment to be fed back to the fire host, as well as fire telephones and fire emergency Broadcasting signal line.

Common fire wire and cable models

1.RVV, RVVP: Copper core PVC insulated PVC sheathed flexible wire/shielded flexible wire, mostly used for connecting electrical appliances and instruments to power lines and transmission lines; RVVP has shielding properties that can resist external signal interference.

2. BV, BLV: PVC insulated wires have good moisture resistance and weather resistance.

3.BVR: PVC insulated flexible wire. Same as BV type, only used in places that require softness during installation.

4.BVV, BLVV: PVC insulated and sheathed wires. Same as BV type, used in places with high requirements for moisture and mechanical protection, and can be directly buried in the soil.

5. BV-105, BLV-105: Heat-resistant 105°C polyneonethylene insulated wires are the same as type B, used in high temperature environments of 45°C and above.

6.BVR-105: Heat-resistant 105℃ polyvinyl chloride insulated flexible wire. Same as BVR type, used in high temperature environment of 45℃ and above.

7.RV: single core copper core vinyl chloride insulated flexible cord. It is used for wiring various mobile appliances, instruments, telecommunications equipment, and automation devices; it is also used as internal installation wire. The ambient temperature during installation is not lower than -15°C.

8.RVB: Two-core flat copper core PVC insulated flexible cord. It is used for wiring various mobile appliances, instruments, telecommunications equipment, and automation devices; it is also used as internal installation wire. The ambient temperature during installation is not lower than -15°C.

9. RVS: Two-core copper core PVC twisted connecting cord. It is used for wiring various mobile appliances, instruments, telecommunications equipment, and automation devices; it is also used as internal installation wire. The ambient temperature during installation shall not be lower than 15°C. Places with high requirements and frequent movement and bending.

10.AVR: Tinned copper core PVC insulated flat connecting cord.

11.RV-105: Copper core heat-resistant 1050C PVC insulated PVC insulated connecting cord.

Zhengzhou Jinshui Industrial Co., Ltd. recommends that everyone pay attention to the selection of cable products and strictly standardize the operating procedures to reduce the occurrence of dangerous accidents.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024