- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on March 27, 2023

What are the common building wire?

what is building wire?

Building wire is an electrical wire that is used for wiring buildings, houses, and other structures. It is designed to be installed in walls, ceilings, and floors, and is typically used to connect electrical devices, outlets, and fixtures to a power source. Building wire is typically made of copper or aluminum, and it comes in a variety of gauges or sizes, which determine the amount of electrical current that the wire can carry. Building wire is often classified by its insulation and rated for specific environmental conditions, such as temperature, moisture, and UV exposure, to ensure it meets the required safety standards.

What type of wire is building wire?

Building wire is a type of electrical wire that is designed and manufactured specifically for use in buildings and other structures. It is typically made of copper or aluminum, which are both good conductors of electricity. Building wire comes in a variety of sizes or gauges, ranging from 14 gauge to 4/0 gauge, and is classified by its insulation type and rating.

The most common types of insulation used for building wire include thermoplastic, thermosetting, and cross-linked polyethylene, which provide different levels of protection against heat, moisture, and other environmental factors. Overall, building wire is a crucial component of any electrical system, as it helps to safely and efficiently distribute power throughout a building.

What voltage is building wire?

Building wire is rated based on the maximum voltage that it can safely handle. The voltage rating for building wire depends on a few factors, including the insulation type, the wire size or gauge, and the intended use of the wire.

The most common voltage rating for building wire used in residential and commercial buildings is 600v, which is suitable for most electrical applications found in these settings. However, there are also building wires available with higher voltage ratings, such as 2,000v or more, which are used in industrial applications or for specific purposes like powering heavy machinery.

It’s important to note that the voltage rating of building wire is just one factor that needs to be considered when selecting the right wire for a specific application. Other factors, such as current-carrying capacity, temperature rating, and environmental conditions, should also be taken into account to ensure that the wire is safe and appropriate for the intended use.

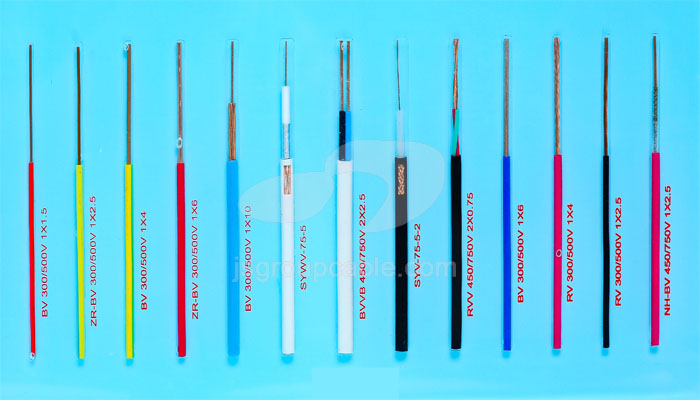

What are the common building wire?

There are several types of building wires commonly used in residential, commercial, and industrial applications. Some of the most common building wires include:

Non-metallic sheathed cable (NM cable)

Also known as Romex, this is a type of building wire that consists of two or more insulated conductors, typically made of copper, enclosed in a plastic sheath. NM cable is commonly used for branch circuits in residential and commercial buildings.

THHN/THWN wire

This is a type of single-conductor wire that is made of copper or aluminum, with a thermoplastic insulation. It is commonly used for building wiring in dry or damp locations, such as in conduit or cable trays.

MC cable

This is a type of metal-clad cable that consists of one or more insulated conductors, typically made of copper, surrounded by a flexible metal sheath. MC cable is commonly used for branch circuits and feeder wiring in commercial and industrial settings.

SER cable

This is a type of building wire that consists of two or more insulated conductors and a bare ground wire, surrounded by a flat PVC jacket. It is commonly used for residential service entrance wiring.

SEU cable

Similar to SER cable, SEU cable is a type of building wire that is commonly used for residential service entrance wiring. However, SEU cable has a round PVC jacket instead of a flat jacket like SER cable.

THW wire

This is a type of single-conductor wire that is made of copper or aluminum, with a thermoplastic insulation. It is commonly used for building wiring in wet locations, such as underground conduit.

XHHW wire

This is a type of single-conductor wire that is made of copper or aluminum, with a cross-linked polyethylene (XLPE) insulation. It is commonly used for building wiring in dry or damp locations, as well as in conduit or cable trays.

USE cable

This is a type of underground service entrance cable that consists of one or more insulated conductors and a bare ground wire, surrounded by a moisture-resistant jacket. It is commonly used for underground residential and commercial service entrance wiring.

MC-HL cable

This is a type of metal-clad cable that is specifically designed for hazardous locations, such as areas with flammable gases or vapors. It is commonly used for wiring in industrial settings.

MTW wire

This is a type of single-conductor wire that is made of copper or aluminum, with a thermoplastic insulation. It is commonly used for machine tool wiring and control circuits in industrial settings.

These are just a few more examples of the types of building wires that are commonly used. As mentioned earlier, it’s important to consult with a qualified electrician or electrical engineer to determine the best type of wire for a specific application, taking into account factors such as voltage rating, current-carrying capacity, insulation type, and environmental conditions.

Precautions for laying building wire:

When laying building wire, there are several precautions that should be taken to ensure that the wire is installed safely and meets applicable codes and regulations. Some of these precautions include:

Follow local building codes:

Building codes can vary by location, so it’s important to check the local regulations before installing any building wire. The codes will specify the requirements for wire size, insulation type, grounding, and other factors, so make sure to follow them carefully.

Use proper tools and equipment:

When installing building wire, it’s important to use the proper tools and equipment to ensure that the wire is not damaged during installation. This can include tools such as wire cutters, strippers, and crimpers, as well as equipment such as conduit benders and fish tapes.

Properly support the wire:

Building wire should be properly supported and secured to prevent damage and ensure that it is not exposed to excessive stress. This can include using conduit or cable trays, and properly securing the wire to prevent it from moving or rubbing against other surfaces.

Avoid sharp bends and kinks

Building wire should be installed with smooth bends and curves, as sharp bends and kinks can damage the wire and affect its performance. If necessary, use conduit or cable trays to make turns and bends.

Test the wire before use

Before connecting any electrical devices or fixtures, it’s important to test the building wire to ensure that it is properly installed and functioning correctly. This can include using a multimeter to check for continuity and proper voltage levels.

Hire a qualified electrician

For larger installations or more complex wiring systems, it’s important to hire a qualified electrician to ensure that the wiring is installed safely and meets all applicable codes and regulations.

By taking these precautions, building wire can be installed safely and effectively, ensuring reliable and efficient electrical power throughout a building.

Compared with other wires and cables, building wire is more closely related to our life, so before selecting and laying, we need to know more about some professional knowledge. I hope this article about building wire can help you.

- Previous:AC cables and DC cables

- Next:When is SWA cable used?

Post categories

Most Popular Posts

-

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024 -

The 135th China Canton Fair

March 20, 2024