- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on May 6, 2023

Overhead Service Wire Type Comparison: Which One is Right for You?

Are you looking for the perfect overhead service wire type for your electrical system, but feeling overwhelmed by the many options available? Look no further! In this blog post, we’ll compare and contrast the most common types of overhead service wire to help you make an informed decision. We’ll cover everything from the simple yet durable bare copper wire to the more complex and specialized insulated wire types. We’ll also discuss the pros and cons of each type, as well as the factors to consider when choosing the right one for your needs. So, whether you’re a homeowner, business owner, or electrical professional, keep reading to discover the best overhead service wire type for you!

If you’re planning on installing or upgrading your overhead service wire, it’s essential to choose the right type for your needs. In this post, we’ll be exploring the different types of overhead service wire available, including bare copper wire, covered line wire, triplex cable, quadruplex cable, ACSR, aluminum wire, copper-clad aluminum wire, high-temperature wire, and insulated wire. We’ll compare and contrast the features, benefits, and drawbacks of each type to help you make an informed decision. So, let’s get started and find the best overhead service wire type for your needs!

Comparing Bare Copper Wire and Covered Line Wire for Overhead Service:

Bare copper wire

It is a simple, uncoated wire that’s made of solid copper. It’s often used for power transmission and distribution in areas where the risk of damage is low. Bare copper wire is durable and long-lasting, making it a popular choice for many applications.

However, bare copper wire is not suitable for all environments. It’s susceptible to corrosion, which can damage the wire and reduce its lifespan. To protect against corrosion and other weather-related damage, covered line wire is often used. Covered line wire is a type of bare copper wire that’s coated with a layer of weather-resistant material, such as polyethylene or PVC.

Covered line wire

It offers several benefits over bare copper wire. It’s more resistant to weather-related damage, including moisture, UV radiation, and temperature changes. It’s also less likely to suffer from corrosion, which can significantly reduce its lifespan. Covered line wire is often used in areas with harsh weather conditions, such as coastal areas or regions with heavy rainfall or snowfall.

Overall

The choice between bare copper wire and covered line wire depends on your specific needs and the environment in which the wire will be installed. If you need a simple, durable wire for power transmission and distribution in a low-risk environment, bare copper wire may be the best choice. However, if you need to protect the wire against the elements and prevent corrosion, covered line wire is a better option.

Triplex Cable vs. Quadruplex Cable: Which Overhead Service Wire Type is Best for Your Home or Business?

Triplex cable

It has three conductors, while quadruplex cable has four conductors. The additional conductor in quadruplex cable allows for increased versatility and options in power distribution.

This cable is often used in single-phase applications, such as residential services or temporary power supplies. Its compact design and relatively low cost make it an attractive choice for these types of applications. However, it may not be strong enough for heavy-duty commercial applications.

Quadruplex cable

It is often used in three-phase applications or in areas where additional power is required. It provides greater versatility than triplex cable, allowing for more options in power distribution. However, quadruplex cable is typically more expensive than triplex cable due to the additional conductor.

When choosing between triplex and quadruplex cable, it’s essential to consider your specific power needs and budget. If you have a simple residential or temporary power supply application, triplex cable may be sufficient. However, if you require more power or have more complex power distribution needs, quadruplex cable may be the better option. It’s also worth noting that some areas may have regulations or requirements for the type of overhead service wire that can be used, so be sure to check with local authorities before making a decision.

The Pros and Cons of ACSR Overhead Service Wire Type:

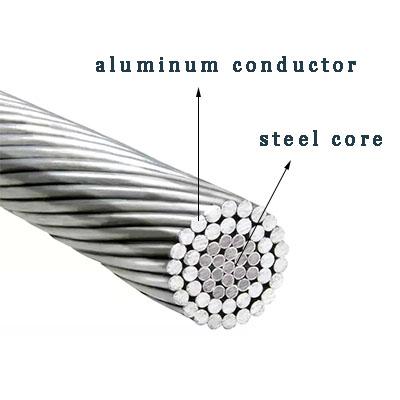

ACSR is an overhead service wire type that is made up of aluminum conductors and a steel core. The steel core provides added strength, making it one of the strongest types of overhead service wire available. This cable is commonly used in power transmission and distribution systems, as well as for overhead ground wires.

One of the benefits of ACSR is its high tensile strength. This allows it to withstand high tension and pressure, making it suitable for long-distance power transmission. Additionally, the steel core provides added durability and resistance to damage, making it a reliable option in areas prone to harsh weather conditions.

However, one of the drawbacks of ACSR is its weight. The steel core adds significant weight to the wire, making it more challenging to install compared to other types of overhead service wire. Additionally, the steel core can increase the cost of the wire.

Aluminum Overhead Service Wire Type: Is it the Right Choice for Your Electrical System?

Aluminum wire is a popular overhead service wire type due to its cost-effectiveness and durability. Aluminum is significantly less expensive than copper, making it a practical choice for long-distance power transmission and distribution. Additionally, it is lightweight, which makes it easier to handle and install compared to heavier wire types.

One of the unique properties of aluminum wire is its resistance to corrosion. Unlike copper wire, which can corrode over time, it is highly resistant to oxidation, making it a reliable option for outdoor applications. This resistance to corrosion makes this wire ideal for use in areas that are exposed to harsh weather conditions.

However, one of the potential drawbacks of this wire is its lower conductivity compared to copper wire. It has a lower electrical conductivity than copper wire, which can lead to higher transmission losses and decreased efficiency. This means that more aluminum wire may be required to transmit the same amount of power as copper wire.

Additionally, aluminum wire can be prone to oxidation, which can lead to issues with electrical connectivity over time. To combat this issue, it is often coated with an anti-corrosion layer or treated with special coatings to improve its conductivity and durability.

The Advantages and Disadvantages of Copper-Clad Aluminum Overhead Service Wire Type:

Copper-clad aluminum wire is a hybrid wire that combines the advantages of both aluminum and copper. It consists of a core of aluminum wire that is coated with a thin layer of copper, which provides the benefits of copper without the added cost. It is significantly less expensive than pure copper wire, making it a practical option for a wide range of applications.

The unique features of this wire is its lightweight compared to pure copper wire. This makes it easier to handle and install, while still providing the benefits of copper conductivity. Additionally, this wire has a lower electrical resistance than pure aluminum wire, which helps to reduce transmission losses.

Copper-clad aluminum wire is commonly used in residential and commercial applications, such as building wiring and power distribution. Its lower cost and lightweight properties make it an attractive alternative to pure copper wire. However, one of the potential drawbacks of this wire is its lower conductivity compared to pure copper wire. This can lead to increased transmission losses, which can impact efficiency.

Another potential issue with copper-clad aluminum wire is its potential for galvanic corrosion. The copper layer on the outside of the wire can react with aluminum, which can lead to corrosion and decreased connectivity over time. To combat this issue, manufacturers often use special coatings or anti-corrosion treatments to protect the wire.

What are the types of Overhead Service Wire insulation?

PVC insulation is the most commonly used type of insulation for overhead service wire. It is a strong and durable material that is resistant to moisture, heat, and chemicals. PVC insulation is also relatively inexpensive, making it a cost-effective option for many applications.

XLPE insulation is a type of cross-linked polyethylene insulation that is commonly used in high-voltage applications. It has a higher temperature rating than PVC insulation and is more resistant to abrasion and chemical corrosion. XLPE insulation is also more flexible than PVC insulation, making it easier to install in tight spaces.

Rubber insulation is a type of insulation that is commonly used in applications where flexibility is a top priority. It is more flexible than PVC or XLPE insulation and is also resistant to abrasion and moisture. Rubber insulation is commonly used in applications where the wire needs to be able to withstand bending and flexing, such as in portable power tools and appliances.

Comparison table of features and benefits of each overhead service line type:

| Overhead Service Wire Type | Features and Benefits |

| Bare Copper Wire | Durable, simple, easy to install, low cost, high conductivity, commonly used for grounding systems and lightning protection. |

| Covered Line Wire | Bare copper wire coated with a layer of weather-resistant material, protects against the elements and corrosion, commonly used for service drops and distribution lines. |

| Triplex Cable | Three conductors, cost-effective, commonly used for residential service drops, versatility in installation. |

| Quadruplex Cable | Four conductors, cost-effective, commonly used for commercial and industrial service drops, high strength and versatility in installation. |

| ACSR | Aluminum conductors and a steel core, high strength and durability, commonly used for long span transmission lines and high voltage applications. |

| Aluminum Wire | Cost-effective, lightweight, corrosion-resistant, commonly used for low voltage distribution lines and residential service drops. |

| Copper-Clad Aluminum Wire | Hybrid wire that combines properties of aluminum and copper, cost-effective, lighter weight than pure copper wire, commonly used for residential and commercial applications. |

In summary, choosing the right type of overhead service line depends on several factors, including voltage requirements, weather conditions, wire length, budget, and local codes and regulations. It is crucial to consider all these factors when selecting the appropriate overhead service wire type to ensure safety and reliability.

Post categories

Most Popular Posts

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024