- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on December 8, 2022

What are the classification and advantages of overhead bundled cables?

Aerial bundled cables do not directly hang ordinary insulated cables or cross-linked insulated cables on overhead poles and towers, but use a special cable similar to the production process of cross-linked cables.

The most common overhead cables are generally single-core, which can be divided into hard aluminum wire structure, hard-drawn copper wire structure, aluminum alloy wire structure, steel core or aluminum alloy core support structure and self-supporting three-core wire structure according to their different structures. Composite structure, the wire core can be hard aluminum or hard copper wire, etc.

1.Classification

(1) The hard aluminum wire structure is light in weight, moderate in tension, easy to bend the cable, easy to install, and low in engineering cost, and can be easily installed on existing poles and towers. This type is often used in general renovation or new construction.

(2) The structure of the hard-drawn copper wire is heavy, but the pulling force is large, and the ability to resist external forces is strong. Even when the tower is broken, the cable can still continue to be energized. The aluminum alloy wire structure is light in weight and strong in tension, and is mainly used in long-span tower systems with a span of 100m.

(3) The support structure of steel core or aluminum alloy core is generally used in 35kV voltage system, and the span is also large. The support line is separated from the three insulated phase lines by square insulating parts. The support line can be used as a lightning protection line. Its biggest advantage The sag is small, and the arc weight is only about 2.4% of the span.

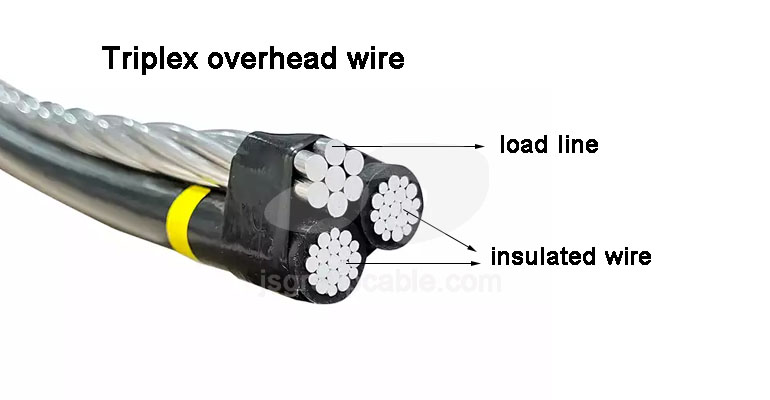

(4) Triplex overhead wire is used in systems with medium span, the most common is 6 triplex overhead wire, the disadvantage of this kind of cable is that the manufacturing length of Triplex overhead wire is shorter than that of single core, there are more joints, and there are outer semi-conductive For the shielding layer, the end of the cable should be equipped with a terminal head or a stress cone structure like an ordinary cable.

2.Main features

(1) High power supply reliability

The use of overhead cables can greatly reduce various short-circuit faults, and the failure rate is about 4-6 times lower than that of overhead bare wires.

The test overhead cable has passed the test of typhoon season and high temperature in summer, and it runs well, and its power supply failure rate is greatly reduced compared with the original overhead bare conductor. Aerial cables will not produce water trees during use, and the insulation quality of the cables will not decline significantly after years of operation.

(2) Power supply security is good

The use of overhead cables reduces personal electric shock casualties. Tests and calculations show that even if the live cable insulation surface is touched by hand, the induced current is less than 0.1mA and 0.2mA, which is much lower than the lethal standard of 50-100mA stipulated in electrical safety regulations. It can be seen that when the overhead cable is energized, when the human body or other animals accidentally touch the insulating surface of the cable, as long as the cable does not break down, it will not cause harm to humans and animals.

(3) Easy to erect and maintain

Aerial cables can be erected on a variety of poles and towers, and can also be erected along the wall. In special cases, they can also pass through the bushes, and the cables can be directly fixed on the tree poles with hardware. In terms of installation, it can be conveniently erected on the original overhead line, using the original cross arm and porcelain bottle, or a full set of supporting hardware and accessories. According to the actual situation on site, the manufacturer can also ask the manufacturer to make special or self-made some special fittings, so the construction is very convenient. There is no need for special inspections for overhead cables, and there will be no short-circuit tripping accidents caused by flashover of branches, littering by residents, or accidental collision of crane arms, etc., thus greatly reducing the maintenance and repair work of the line.

(4) Economical and reasonable

Although the use of overhead cables is more expensive than the use of overhead bare conductors, it is cheaper than ordinary underground cables. Therefore, although the one-time investment of overhead cables is slightly higher, the operating cost will be significantly lower than that of overhead bare conductors considering other factors. For example, the use of overhead cables makes the line gallery smaller, and even multiple lines share one tower, which reduces the cost of land acquisition and land occupation. There is no need to cut down and trim trees under the line during operation, which saves cutting and trimming costs. The most important thing is to reduce line failures and their direct or indirect damages incurred. Therefore, its comprehensive cost is obviously lower, more economical and more reasonable.

Post categories

Most Popular Posts

-

The 135th China Canton Fair

March 20, 2024 -

What are the laying methods of copper core wires and cables?

January 9, 2024 -

What are the advantages of aluminum conductor cables?

December 14, 2023 -

Characteristics of high temperature wires and cables

December 7, 2023