- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

SWA Cable

SWA Cable

SWA cable is commonly used in industrial and commercial applications where the cable is likely to be exposed to rough conditions or where there is a risk of damage from heavy machinery or other equipment.

- Description

1.Application Of SWA Cable

SWA cable is commonly used in a variety of applications, including:

Power transmission:

It is often used to transmit power in industrial and commercial settings, such as factories, construction sites, and power plants. The steel wire armor provides extra protection against physical damage, making it ideal for use in areas where there is a risk of impact or crushing.

Underground installations:

SWA cable is often used in underground installations, such as those for lighting or power distribution. The steel armor protects the cable from damage caused by rocks or other objects in the soil, reducing the risk of failure.

Marine and offshore installations:

It is also used in marine and offshore installations, where it provides protection against saltwater and other harsh environmental conditions.

Data transmission:

SWA cable is also used for data transmission, particularly in industrial settings where there is a risk of interference or damage to the cable.

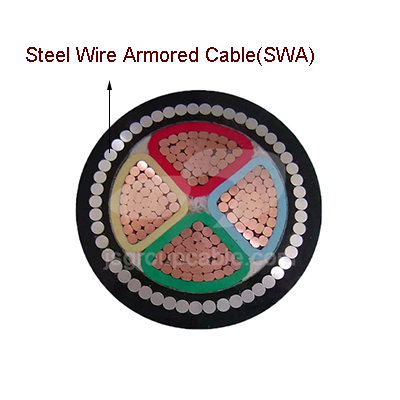

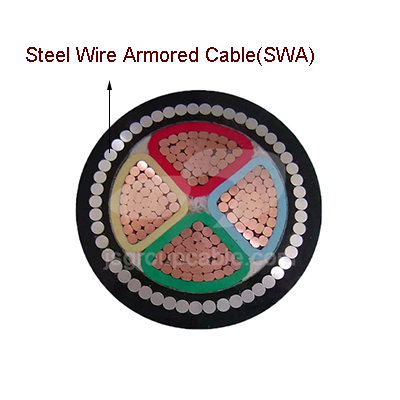

2.Construction Of SWA Cable

The construction of SWA cable typically consists of the following layers:

Conductor:

The conductor is the innermost layer of the cable and is typically made of copper or aluminum. It is responsible for carrying the electrical current.

Insulation:

The conductor is surrounded by a layer of insulation, which is typically made of PVC, XLPE or other suitable material. The insulation is designed to protect the conductor from contact with other conductors or with the outer layers of the cable.

Bedding:

The insulation layer is covered by a layer of bedding, which is typically made of PVC or LSZH material. This layer provides a protective barrier between the insulation and the armor layer.

Armor:

The armor layer is made up of a series of steel wires, which are wound around the cable in a helical pattern. The steel armor provides extra protection against physical damage and also helps to reduce the risk of electrical faults caused by damage to the cable.

Sheath:

The armor layer is covered by a layer of sheathing material, which is typically made of PVC or LSZH. The sheath provides a protective barrier between the armor and the environment.

Product Category

Latests News

-

The 136th Canton Fair welcomes you to participate!

October 12, 2024 -

High temperature cable introduction

July 26, 2024 -

Kenya Power and Energy Exhibition 2024

June 11, 2024 -

Introduction of rubber sheathed cable

June 5, 2024