- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on February 2, 2023

Production principle and performance of XLPE insulated cables

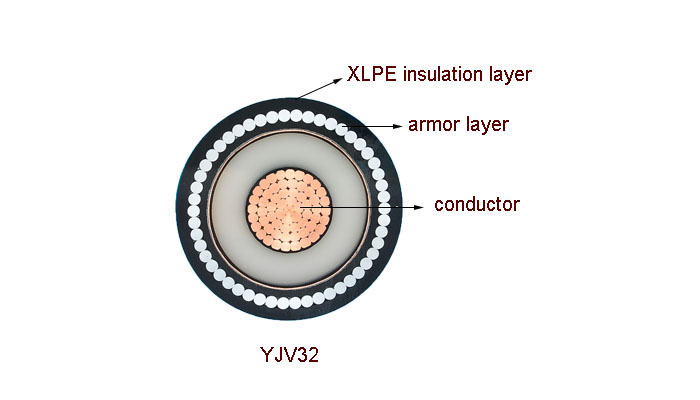

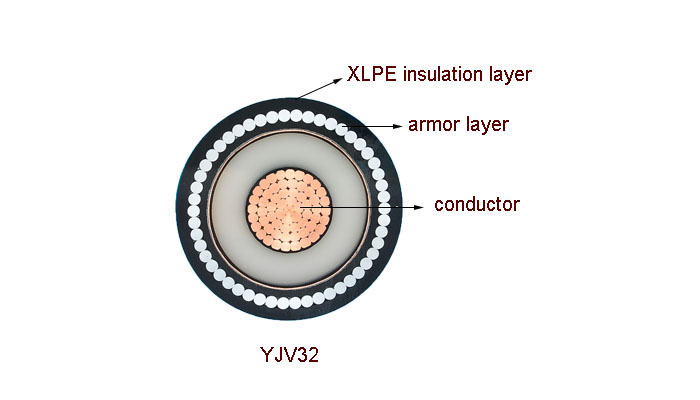

XLPE insulated cable is a cable made of XLPE as insulating material. It is suitable for distribution network, industrial equipment or other large-capacity power consumption areas. It is used for fixed laying at AC 50Hz and rated voltage at 6kV-35kV. In the power transmission and distribution lines, the main function is to transmit electric energy.

Due to the continuous development of the modern power industry, the technology has also been continuously innovated. The cross-linked polyethylene material is mainly to change the polyethylene molecule from a linear molecular structure to a three-dimensional network structure, from a thermoplastic material to a thermosetting material, so that its working temperature From 70°C to 90°C, the current carrying capacity of the cable is obviously improved. The product structure of XLPE insulated cables is simple, the production cycle is short, it is relatively easy to install and maintain, and it is not limited by the drop when laying.

What is the principle of polyethylene crosslinking?

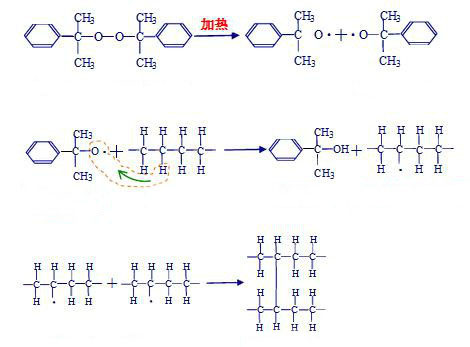

Polyethylene contains two elements, carbon and hydrogen. Both hydrocarbons belong to high molecular compounds and have a linear molecular structure. They are in solid state at room temperature, and they are crystalline and amorphous in solid state polyethylene. Polyethylene has excellent electrical insulation properties, but its heat resistance is not very good, which affects its use as cable insulation materials. Due to the weak intermolecular interaction in the amorphous region, its mechanical strength decreases significantly when it approaches the melting point of polyethylene, and its resistance to cracking also becomes poor.

When the linear macromolecular chain undergoes chemical or physical methods, the polyethylene molecule is transformed from a linear molecular structure to a main network molecular structure, that is, thermoplastic polyethylene is transformed into a thermosetting cross-linked polyethylene. This process is called cross-linking. Cross-linked polyethylene has greatly improved heat resistance and mechanical properties, reduced its shrinkage, made it no longer melt after being heated, and maintained excellent electrical properties, so it began to be widely used in power cables insulation material.

What are the properties of XLPE insulated cables?

1.Insulation performance: With the continuous innovation of technology, XLPE is used as the insulation material, which maintains the excellent insulation properties of PE, and further increases the insulation resistance on this basis. Its dielectric loss tangent is very small and is not greatly affected by temperature.

2.Heat resistance: Technological innovation makes the XLPE with three-dimensional network structure have very good heat resistance, it is not easy to decompose and carbonize in high temperature environment, the long-term working temperature can be as high as 90 ℃, and the service life can reach 40 years.

3.Mechanical properties: Due to the establishment of a new chemical structure between molecules, XLPE has greatly improved in terms of hardness, stiffness, wear resistance and impact resistance, and also made up for the easy The disadvantage of cracking due to environmental stress.

4.Chemical resistance: XLPE material has strong alkali resistance and oil resistance, and its combustion products are mainly water and carbon dioxide, which is less harmful to the environment and meets the requirements of modern fire safety.

Types of XLPE insulated cables:

1.XLPE insulated flame-retardant cable: it can prevent the fire from spreading in the cable line, and can avoid the expansion of fire accidents, thereby reducing the loss caused by fire. It is suitable for subways, tunnels, high-rise buildings and other places with high laying density place.

2.XLPE insulated halogen-free low-smoke flame-retardant cable: it has excellent flame retardancy, corrosion resistance and low smoke concentration, and is an environmentally friendly cable. Suitable for some crowded places.

With the continuous development of modern society, the requirements for industrial production are getting higher and higher. In the process of continuous innovation, all aspects are pursuing more advanced technology. Jinshui Wire&Cable Group is constantly pursuing innovation in production to provide customers with high-quality , Safe wire and cable products, and provide guaranteed after-sales service, so that customers are safer and more at ease in the process of using the product.

Post categories

Most Popular Posts

-

The 135th China Canton Fair

March 20, 2024 -

What are the laying methods of copper core wires and cables?

January 9, 2024 -

What are the advantages of aluminum conductor cables?

December 14, 2023 -

Characteristics of high temperature wires and cables

December 7, 2023