- Offices Time:24 Hours Online

- Email:[email protected]

- WhatsApp:+8618339938759

Posted on January 17, 2023

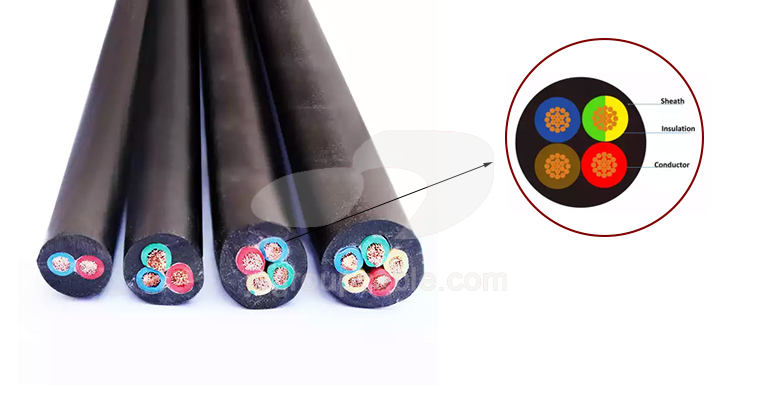

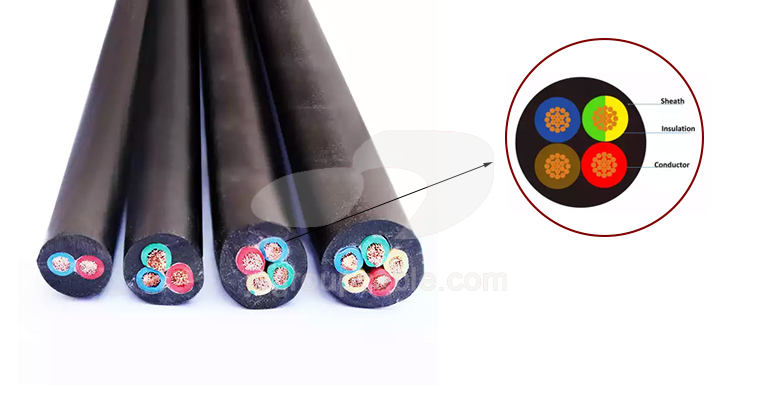

Features and selection of rubber sheathed flexible cable

Among our commonly used power cables, rubber sheathed flexible cable is also one of them. It is a soft and movable cable variety with multi-strand fine copper wire as the conductor, and rubber insulation and rubber sheath. Generally speaking, it includes general-purpose rubber-sheathed flexible cables, electric welding machine cables, submersible motor cables, radio device cables, and photographic light source cables. So what are the uses of rubber-sheathed flexible cables and what are the selection principles? Here is a brief introduction.

The use of rubber sheath flexible cable

Rubber-sheathed flexible cables are widely used in various electrical equipment, such as household appliances, electric machinery, electrical equipment and portable power cords for appliances, and can be used indoors or outdoors. According to the external mechanical force of the cable, the product structure is divided into three types: light, medium and heavy, and there are appropriate connections in the section. Generally, light rubber-sheathed flexible cables are used in household appliances and small electric equipment, requiring softness, lightness, and good bending performance; medium-sized rubber-sheathed flexible cables are widely used in agricultural electrification except for industrial use, and heavy-duty cables are used in such as port machinery, Searchlights, large-scale hydraulic irrigation and drainage stations for family businesses, etc. This type of product has good versatility, complete series of specifications, good and stable performance.

The characteristics of rubber sheath flexible cable

1.Unmatched flexibility by other wires and cables;

2.Good electrical insulation performance and chemical stability;

3.Good physical and mechanical properties and wear resistance;

4.Oil resistance, flame retardant, cold resistance, heat resistance and other requirements.

Selection principle of rubber sheath flexible cable

Since there are many types of rubber-sheathed flexible cables, when purchasing cables, how to choose a cable that suits you according to your usage has become a key issue.

1.Understand the performance indicators of all aspects of the cable in detail. Aiming at some conditions such as the wear resistance, compression resistance and service life of the rubber-sheathed flexible cable, conduct detailed inquiries and understand, and then judge whether it is in line with your own use conditions. And whether there is a national compulsory certification mark after the cable production is completed, and whether the company has a corresponding quality assurance certificate, etc.

2.The influence of the surrounding environment on the use of the cable During the use of the cable, in addition to being limited by its own use conditions, there are also some external environments that play a decisive factor on it, such as: if there is interference from the magnetic field, then the cable needs to be added. There is a shielding layer; if it is a welding robot, due to the long working time and high temperature, it will have a great test on the outer sheath of the cable, so the selection should be made according to the actual situation.

3.Clarify the use function of the cable Whether it is a control cable or a rubber sheathed cable, no matter how excellent the performance of the cable is, what we have to do is to install the cable in a position suitable for its use. Only in this way can the original quality of the cable be achieved. It has excellent performance and service life.

Installation requirements for flexible rubber sheath cables

1.During installation, the cable head must be protected from moisture and dust. According to the site environment, build a dustproof shed if necessary.

2.In the case of ensuring the quality, the working time of the cable head should be shortened as much as possible.

3.The cable accessories used should check in advance whether the specifications are consistent with the cables, whether all parts are complete, the date of production, and the packaging (tightness).

4.Before installation, the cable head must be protected from moisture and wrapped in advance; the insulation of the cable should be measured before operation to ensure the insulation requirements, and records should be made to ensure the connection quality of the finishing process.

Post categories

Most Popular Posts

-

The 135th China Canton Fair

March 20, 2024 -

What are the laying methods of copper core wires and cables?

January 9, 2024 -

What are the advantages of aluminum conductor cables?

December 14, 2023 -

Characteristics of high temperature wires and cables

December 7, 2023